Hi Roger

Just to be sure, was the same distributor used before and after the engine rebuild?

If so...because you say you drove this engine for 18 years without this problem, and it suddenly showed up after a rebuild, I suspect the problem is not with your distributor.

So, that brings me to questions regarding the rebuild.

Did you do the rebuilding yourself? Or did someone else do it?

And, what exactly was done?

You say the block is from 1950... exactly what parts are from 1940, and what parts are new?

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

When I rebuilt the motor, I spared no expense. Everything in the block and head is new except the rocker assembly and push rods. The elderly machinist who did the work was in his late 80s. Deceased now. He ordered all the parts and I assembled the motor. One exception. He pressed the cam bearings in. Im starting to wonder if somehow there's too much clearance on the cam and the noise I hear is the cam beating the bearings to a pulp? New cam , new bearings, but are they right? Is there a difference between '40 and "50 bearings and journals? One year cam another year bearings?

Noise from the camshaft really shouldn't be effected by timing.

And, camshaft bearings were the same part for all years of 216 engines.

On the other hand... piston slap, wrist pin noise, and lower connecting rod bearing noise can all be effected by speed and timing.

I'm interested in the clearances your engine was rebuilt to.

What piston clearance was the block bored to? Aluminum pistons? Or cast iron?

What procedure did you use when you shimmed the main and rod bearing clearances?

Also, you say the entire block is 1950.

So where does 1940 come into the picture here?

Just wondering, as the pistons were changed from domed to flat tops for 1941 and the head was changed to suit.

A 1940 head on a 1950 block should give a compression ratio so low that spark knock should be impossible.

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

Thanks for your interest in my problem. Piston slap, connecting rod bearing noise, or wrist pin noises are sounds I've been too familiar with over the years. Its not them. cyllinders were bored .030, crank turned .020. New aluminum flat top pistons, new wrist pins. rods milled for inserts with one shim. I used Plastigage on each bearing to check tolerance. In the head, new valves, seats, springs. Head was shaved very slightly. New cam, new lifters, old pushrods which I checked for straightness. New oil pump ,rebuilt my harmonic balancer. And as I said before, the rocker assembly I did not change, rockers had .001 or less clearance with the shaft. zero wear on the shaft. number on the head is3885517 81

I know for sure the block is 1950.

A new development in the saga of this strange noise. The noise worsened. So I took my trusty listening device (1/2"pvc pipe) and centralized the noise in the oil pan. I took the pan down and it appears that there is some interference between the rod caps and the oil troughs. The evidence is the edges of some of the troughs are turned so as to have knife sharp edges on the sides of the top edges, similar to that of a hook scraper for wood. Since the noise began at rebuild and the use of some rods that were machined for inserts, i wonder if they are the wrong rods or caps. Number on side of the rod is 383251. Can't find it anywhere. The stamp on the distributor ledge is HAM110607. I measured the distance from the outsides of the ridges on the rods at 1.220 -1.280". The tops of the troughs measure .920 - .960". Troughs are all secure, equally spaced and pristine except for the edges being turned. Also measured vertical distance from the edges of the pan, they were equal. Also no scrape marks inside the troughs. Do I have the wrong rods? As a solution, I wonder about doubling the pan gasket rather than tearing a new motor apart.

It's important that the troughs, nozzles and dippers are aligned correctly for your rods to get sufficient oil. If not, your new engine will not live long. I just sold a set of aiming tools. The Filling Station rents them I believe. You should obtain a set and make sure everything is as it should be. It sounds like such may not the case.

7046 old site posts

Save a life, adopt a senior shelter pet

There are many good people. If you can't find one, be one.

1938 Master Business Coupe

1953 210 Sedan

I connected a water hose to the nozzle inlet pipe and tested the nozzles. All shooting the same. Even were they a problem, that would explain the racket and the turned sharp edges on some of the troughs. What I need to know is did the machine shop buy me the wrong rods? And is an easy fix using double pan gasket. Would that affect oiling the rods?

Hi Roger

I asked the questions I asked because I was pretty sure you had bottom end trouble.

My next question was going to be about adjusting the nozzles etc supplying the rods.

It sounded to me like possibly you were getting a little oil to the rods at lower RPMs, but not enough at higher revs (yes that is possible).

Pictures of what you are seeing would help, but in the mean time...

I'm not seeing the rod number you have anywhere either, so can't say what you have.

I can say that those ribs/ridges on the rods shouldn't get anywhere near the oil troughs.

Maybe I missed it, but I don't see any mention of the sheet metal dippers that are held to the bottom of the rods with the rod bolts and nuts.

They are there, right?

Also, it's impossible to "eyeball" the aiming of the nozzles.

You will need setting gauges Tiny mentioned to do it right.

Mine looked okay visually as well, but when I used the gauge I had one stream only half on target that I had to correct.

Do NOT try to correct the problem with 2 gaskets.

Only one gasket of the original thickness should be used.

There are many thinks that could be wrong here, but just as an example scenario...

At low RPMs, the nozzles essentially just dump oil into the troughs where it is picked up by the dippers.

At higher RPMs, the flow from the nozzles becomes a jet of oil that points at and strikes the dipper through an extended part of the crank revolution.

If the nozzle isn't aimed exactly right, it can dump oil into the trough at low RPMs, but miss the dipper AND the trough at higher RPMs.

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

Fast forward to 7 minutes to cut to the chase: https://www.youtube.com/watch?v=CCtJlgtZnBY&list=PL1_6uktRWO-5i3hsvheW6EQynOo_dDfQ0&index=5

7046 old site posts

Save a life, adopt a senior shelter pet

There are many good people. If you can't find one, be one.

1938 Master Business Coupe

1953 210 Sedan

You beat me to it! 🙂. 👍

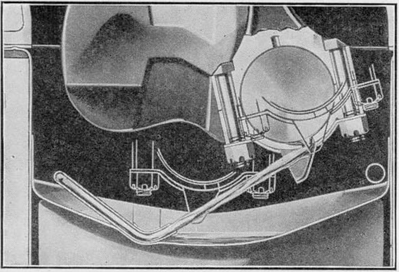

I was going to post that as well as this cross section, both showing that the rods shouldn't come anywhere near the troughs:

I would also add that the film you link to is from about 1937.

The oil pump volume was increased in I think 1940, and the nozzle outlet diameter was slightly decreased I believe, resulting in a longer stream of oil than shown in this video when the dipper comes around and hits it again.

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

One more thing.

Your engine number does indeed confirm that the block is a 1950 passenger car engine made at Tonawanda for use with a regular (not heavy duty) clutch.

PS

You said you spared no expense.

By any chance was the engine "hot rodded" by drilling the crank between the main and rod journals to pressure lube the rods?

Some people did that in the past thinking the dipper system was inadequate.

They were wrong.

The "pressure stream" system was a fantastic system if adjusted and taken care of properly.

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

Bob, since my last post, the noise worsened and it definitely sounded from the babck of the oil pan. Pulled it down. Oh me! # 6 rod had a spun insert. The tan was still in it's slot but sheared off. Im told the tang is for location only and not to keep the bearing from spinning.

When I got the bearings some .012 brass shims came with them. I was told to use the shims. So I did. I believe those shims prohibited tightenig the rod on the bearing shell enough to keep it from spinning. Thats the noise Ive been hearing. At least thats what I think now.

You are correct, the tangs aren't for keeping the bearing shells from turning.

"Crush" is.

The bearing shell is kept tightly in place by what is called "bearing crush".

When the shell halves are set into the rod and cap, the parting edges SHOULD project a few thousandths of an inch above the flat surfaces where the cap and rod meet.

That "crush" MUST be there so that when the cap is tightened onto the rod, the projection crushes the bearing shell tightly into the rod and cap, keeping it from turning, and ensuring proper heat transfer.

IF there are shims, they MUST extend in over the parting surfaces of the shells and nearly to the crankshaft journal.

For this reason, if everything is right, it doesn't matter how many shims are installed, the bearing shells should be held to the proper tightness in the connecting rod.

It would still help a lot if you could post some pictures of what you are seeing. 🙂

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

I will try to figure out how to post pics on here.

Seems to me though that the .012 shims would make the bearing enclosure exactly .012 greater diameter. Thus reducing or eliminating bearing crush. Doesnt seem those two tiny slivers of brass between the meeting edges of the bearing halves worked. I have the spun bearin to prove it.