Stovblt & Paul,

I had thought my post was complete until I read Stovblt's. He did a masterful job of commenting.

I thought about piston slap and wrist pin noise but didn't want to confuse readers. I am glad that Stovblt did as it may be what is actually happening.

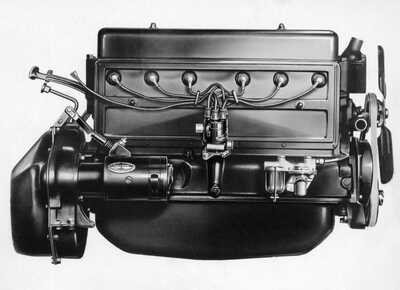

How sweet the roar of a Chevy four

Participant on Chatter since 11/22/2001

19758 posts on the former Chatter site

I agree with you that Stovblt’s response makes this a great forum.

I thought about his comments and think my problem is not being familiar with the sound of the engine.

I took the car for a drive and thought about both your comments. I feel that I am not familiar with the sound of the engine. I think that I have been retarding the spark too much while climbing a hill or on acceleration. This is why I questioned the distance that the spark button traveled back to retard the engine. I need to feel that button does not need to be completely pulled back.

The car was quiet while idling and no knocking sounds, so I do not think it is a bearing. I will say that changing the spark plugs to .040 did make a difference in the performance of the car.

My plan is to drive the car and get more familiar with it and then change the timing to 18 degrees BTDC. I will talk to a local mechanic about using a borescope next week.

This is the first early 6-cylinder engine I have worked on as my experience has been with the early Chevy 4-cylinder engine. I own a 1926 touring and a one-ton truck.

Thank you for all of your help.

Paul

I wanted to update you on my 29 Chevy and thank you for all of your help. I set the spark plugs to .040 and it improved the performance. I rebuild the carburetor as well. What does increasing the spark gap accomplish? The car sounds and runs much better.

@paul-baresel increasing the gap size increases the spark area exposed to the air-fuel mixture, which maximizes burn efficiency. From an internet search. I also think it increases the spark due to the larger gap requiring more voltage .

7472 old site post

I will agree with you on this topic. It may not be a hotter spark with a large spark gap, but it is a longer in length spark for ignition. I remember when I was into model t fords, that it was discussed to get a hotter spark by increasing the spark gap from .25 to .30. The improvement was to go from a 6 volt dc to up to a 21 v ac the magneto. The car always ran better off of the magneto than on the battery, so the long spark theory I feel is correct. Thanks Paul

Magneto spark these days is generally preferred for high speed engines as it creates a higher voltage / amperage spark where the battery and coil (kettering) system is prefered for slower running engines.

Tony

I have 3 29s, 2 running and one not running. One car responded very well to the 18 degree advancement as suggested by Bill Barker some years ago. The other car was happier at about 15 degrees. You will have to play around with where your car runs best.

@paul-baresel Paul, Am I reading this right? The picture you posted says to bring Cylinder 1 to TDC then rotate back to 15 degrees BTC then rotate the distributor until the points begin to open. All that makes sense. But then It says to connect the #1 cylinder wire directly opposite of the rotor pointer.

That position makes sense based on the pic of the distributor with cylinder labels in the repair manual. That picture does not give you an orientation as far as what direction you're looking at it from, it’s an overhead view. If that is correct my wires are 180 out of time. I got the engine with the wires already on it. So when I replaced them I just copied what was there, one at a time, knowing I would check the timing once I got ready to start it.

If I got this right, with the #1 cylinder at TDC or 18 degrees BTC the rotor should be facing around the 1 o’clock position when looking from the passenger side. Which would mean the number 1 cylinder wire would connect to the 7 o’clock position.

With the engine at TDC or 18 degrees BTDC, and cylinder number 1 at the end of it's compression stroke (or thereabouts), the rotor should be pointing directly under the tower on the cap serving the number 1 cylinder.

Normally Chevrolet originally installed the distributor such that the number 1 wire would be at about the 5 o'clock position on the cap.

That really isn't vital, just important to some of us who are "anal" about correctness (sometimes me 😉).

Just be sure when re-installing the distributor that you are sure it's completely down and engaging the slot on the oil pump.

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

@ole-olson Ole, I have 2 marks on my fly wheel. One appears to be TDC the other is about 2 inches clockwise and looks like a 12. Both markings are pretty worn. So I rotated the engine so that the #1 cylinder (closest to the radiator) was at the top of the compression stroke. I had the plug out and could feel the air blow out.

That put me very close to the TCD mark I then rotated the engine to the mark that looks like a 12. In that orientation the rotor is facing the 1 o’clock position (looking from the passenger side). This is where my #1 wire is. I then rotated the distributor clockwise and then back just until the points closed. I read this somewhere. The final position to the rotor is close to the #1 wire but not exactly on it.

Am I off the mark? I can’t rotate the distributer to be exactly on the #1 wire the grease cap hits the block. The rotor is offset clockwise form the wire just a bit.

Also the distributor body is down as far as it can go so i believe the oil pump is engaged. I oriented the pump before I put earth distributor back in. Soit slipped right in.

Thoughts.

That sounds like you've got it right.

Make sure the spark button is pushed all the way in when setting the timing.

The 12 mark is 12 degrees before TDC which was what they were originally set at.

A lot of people are going to 18 degrees because newer gasolines are much higher octane than what was available in 1929 and they feel they get better performance at that setting.

But I'd try 12 degrees first.

PS

Also, it's a good idea to find TDC like you did, then rotate counterclockwise PAST the 12 a ways, then back clockwise just to the 12 mark.

That takes the slack (gear backlash etc) out the equation and ensures a closer setting.

PPS

Having number 1 at 1'oclock is just fine. 🙂

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

The old paint on the distributor wil probably show you if you are fully down in place.

Comparing to the above pictures MAY help, but I think the difference between being fully down and not is only about 1/2 inch.

If you see an unpainted or shiny band on the distributor shank about 1/2 wide above the the edge of the block, be suspicious.

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

Also,

The tip of the rotor won't completely line up with the tower contact, because as the centrifugal advance starts to come in it changes the alignment of the rotor in relation to the tower at the point of ignition.

So.. throughout the range of the centrifugal advance, the position of the tip of the rotor at the point of ignition "sweeps across" the tower contact.

PS

Just to clarify...

At low RPMs when the mechanical advance has not come into play yet, at the point of ignition the end of the rotor will be a little past (clockwise from) the tower contact.

At high RPMs when the advance has fully come into play, at the point of ignition the end of the rotor will be a little ahead of (counter clockwise from) the tower contact.

This is of course because the advance mechanism works by turning the point cam (which the rotor is mounted on) in relation to the distributor drive shaft.

Okay, enough long winded trivia for today. 🙂

Ole S Olson

Saskatoon, Sask, Canada

1946 DR 3/4 ton stake

1139 old site posts

@ole-olson Thanks Ole, I think the distributor and timing are good for a test. I just need to take the carb off and fix the needle valve and float. The choke is stuck as well. I had a feeling the float was going to give me trouble. I have another carb but it looks rougher than this one. I also have a 1931 carb, not sure I’d that would work.

Thanks for all the help today!