For what it's worth, that looks great to me. I can think of no reason not to continue if you are satisfied. Only a diehard expert might pick up on a few oddities.

Russell

Nick

This looks great as is. I think once the bumper brackets and bumper are installed it will be difficult for even most art deco truck enthusiasts to recognize the difference.

That looks much better with all the gaps closed up. You mentioned the running board mounts needed to be repositioned which I doubt as they are located by the front fenders unless you moved them as well. As it sits now I think it is definitely worth continuing.

Tony

Tony,

Before I unbolted the running boards from their frame-mounted brackets, there was a gap between the forward end of the running boards and the aft end of the front fenders, as may be seen in the photos attached to the original post. As soon as I slid them forward about the same amount as the cab was moved forward, they lined up nicely with the front fenders. (Since we have determined in this thread that my cab is sitting on a later (longer) chassis, it appears that extra length shows up somewhere between the front of the frame and the location of the running boards.)

I am thinking that I will create a plate to bolt to the running board frame-mounted bracket that will extend forward under the new position of the running board to allow the running board to be bolted securely to the plate. There is only about a 1 1/4" change in the bolt locations, so I am guessing (hoping) that a 1/8" plate would be strong enough.

For the attached photos, I just put a scrap of wood on top of the existing frame-mounted bracket to hold the running board at approximately the same height it would be sitting on the bracket.

Nick

Nick Gurin

Taos, New Mexico

1940 KC 1/2 Ton Pickup

Nick,

looks like the running board connections are tack/spot welded on. If so, you can cut the welds off and re weld them in the place you need them to be.

mike

If yours are like my 38 the running boards are shaped to fit the rear of the front fender so that will be the main determining factor. The support brackets on mine were bolted on and I suspect yours were also.

Tony

Mike,

I don't have a welder or any welding skills! (Yes, I was certified as a TIG welder in 1977, but NEVER welded since that course!) I figure that I can make a mounting plate that will bolt to the existing frame-mounted brackets and shift the bolt holes for the running board 1 1/4" forward. But please, if you think that this is a bad idea - let me know!

Tony,

I have attached a photo of the forward end of the running board with bolts through it and the holes in the rear of the front fenders. It seems to line up without any real issue.

The running board frame-mounted brackets are riveted to the frame. There are brackets spot welded to the underside of the running board that normally are bolted to the frame-mounted brackets. Since the running boards have been moved forward about 1 1/4" due to the 1940 cab being shorter (front to back) than the cab on this later frame would have been, the brackets on the running boards no longer line up with the frame-mounted brackets.

Nick

Nick Gurin

Taos, New Mexico

1940 KC 1/2 Ton Pickup

I have no idea what welders charge in your neck of the woods but it would be pretty simple to drill the spot welds out, move the brackets to where you want them then plug weld them back in place. You would have the holes in the running boards where the brackets were originally welded to fix but that's easy. Have the welder weld them shut. Grind them smooth, add the necessary filler to your satisfaction then top coat as you wish.

7046 old site posts

Save a life, adopt a senior shelter pet

There are many good people. If you can't find one, be one.

1938 Master Business Coupe-Sold, now living in New Jersey

1953 210 Sedan

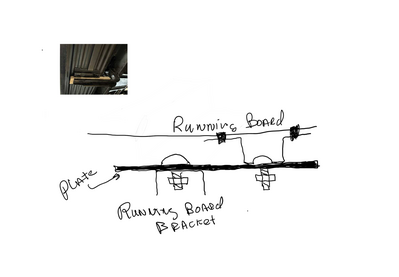

Another solution is to just use a thin plate between the two brackets. Heavy sheetmetal would prob work….. the brackets appear close enough…..

drill some holes in the sheetmetal to correspond to the bracket holes. No need to modify your existing metal (maintains it's integrity for future) and, no welding !!!!!!

Mike

@mike-rabaut You're quite the artist there Mike. 😀

7046 old site posts

Save a life, adopt a senior shelter pet

There are many good people. If you can't find one, be one.

1938 Master Business Coupe-Sold, now living in New Jersey

1953 210 Sedan

Your drawing is what I was picturing doing. I was thinking about using 1/8" plate. Since the brackets are so close, there shouldn't be much of a tendency for the metal to bend.

Also, as you mention, I would prefer to do as little modification to the components I am using as possible so that in 100 years, someone will have unadulterated parts to work with!

Nick

Nick Gurin

Taos, New Mexico

1940 KC 1/2 Ton Pickup

1/8 should be plenty. You will also be affecting the alignment of some other components but I don't think that would be much of an issue.

Mike