My best tip is to contact EARLY CHEVROLET PARTS, Gary Wallace: http://www.earlychevyparts.com/ , email chev4cyl@charter.net.

Ten-eleven years ago I bought from him a good used propeller shaft which I installed in my 1922 490, together with a NOS ring gear 34 teeth and a good used pinion 9 teeth, both with spiral cut teeth. I bought the R&P-gears from a friend in Sweden who worked on a 1920 Four-Ninety restoration project, (straight cut R&P-gears, like the ones for Ford T, so he didn´t need the spiral cut gears). He also restored a Ford T, and he found these two parts in his Ford T used and NOS parts box!

I think they are very rare, also in the US, so I wish you good luck!

Good to hear that spider gears and bearings looks OK.

swedechev

234 posts on "Old forums" 1912-1928 and 1916-1922-Model 490

@per-ake-larsson I am working with Gary now. Thanks for you quick reply and wealth of knowledge on the 490. Mike

Still looking for a ring rear for our 1922 Chev 490. It has 34 teeth and the pinion has 9 teeth. It is 8 inch diameter.

Have collected as many parts as we could and hope to put it back together next week.

Have a new pinion, 10 ring gear bolts, thrust washer and shims from Snyder’s, propeller shaft housing bushing from Billy Possum and a new 1307 new departure bearing. If you have a new ring gear let me know. If not I will be putting the old one back in.

Any suggestions are welcomed. Thanks Mike

@michael-mcdonald Mike, My friend has a couple of early Chevy rear axle assemblies in the woods. I think I can see enough of your housing, torque tube, etc, to tell if they are a match to yours. I noticed them on Thursday when I was there looking to see if he had anything that would help Ed Archer with his truck axle repair.

Mike.

Many Miles of Happy Motoring

3469 Posts on Old VCCA Chat

@35mike Thanks Mike. I will be trying to put the car back together on Friday next week. If you need any pictures or measurements please let me know. I appreciate all your help.

@michael-mcdonald Mike, We need to talk. I will look through my email for your direct contact address.

Mike

Many Miles of Happy Motoring

3469 Posts on Old VCCA Chat

Well things didn't go to well on Friday. We couldn't get the old ring gear back in place to put the 10 ring gear bolts in. We tried heating it on a hot plate no luck. I wasn't expecting this the ring gear came off with only a few taps with the hammer. I will take it to the machine shop Monday and get them to put it on.

Got the ring gear back from the machine shop. They were able to get the 10 ring gear bolts on by heating the ring and drawing it in slowly a bit at a time with longer fine thread bolts that we didn't have.

Have a new set up for the axle so it is easier to work on.

Waiting for a back lash gauge. The new pinion is on hope the old ring gear holds up and doesn't ruin the pinion.

If anyone has some tips or specifications on how it should go back together I would appreciate the help this is my first time working on a rearend. Thanks Mike

Mike

When I did this repair, it was my first time working on a rear end. I have a lot of notes (in Swedish language) and a lot of pictures. I hope you will have tips from someone more experienced than me!

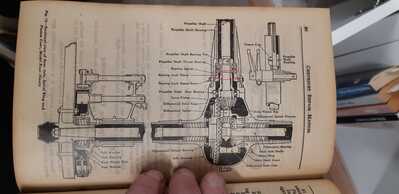

I had quite a lot help from ”Chevrolet Repair Manual 1918‑1924”, although it has its focus on the earlier models, up to 1921. I also had quite a lot of help from “The Model T Ford Front and Rear Axles”. Specially as support for doing the different moments in a proper sequence.

If you have not done these moments already, I suggest that you start with these.

(the right end of the axle up)

Check that the pinion fits the propeller shaft end. If necessary, grind with valve grinding paste, first course (heavy?), then fine.

Adjust the two axle halves end play. Use fibre spacer, grind the spacer until you still have some resistance when you twist the axles.

Check that the axle housings are straight (“axle housing alignment”). I used a used hub on the left (lower) axle half ant the wheel on the right (upper) axle half, so I could check that the left axle end was in the middle of the hub opening, with moderate play.

Check that the propeller shaft is straight, it must be easy to twist. I used a new front bushing in the propeller shaft housing.

After that, the most time-consuming moment: checking and adjusting to get a proper play between the pinion and the crown wheel (back lash). The Chevrolet manual says ”the back lash should be very slight”.

Every test I made I used oil paint on three-four teeth on the pin ion to check the marks from the crown wheel in the oil.

I made a simple brake on the used hub which I could tighten with a spanner. See this picture.

I thightened the brake so hard that I had to use my full strength to twist the axle with the wheel that I had put on the right (upper) end of the axle.

After testing a lot of combinations of thickness of the paper gaskets (propeller shaft housing – axle housing and axle housing halves), shims for the thrust bearing – differential house and even shims for the crown wheel my friend and I were satisfied when we estimated the play (back lash) to 0,10 mm (.004”)

swedechev

234 posts on "Old forums" 1912-1928 and 1916-1922-Model 490

@per-ake-larsson I was able to borrow a late edition of the Chevy 490 manual which actually makes mention of the Four-Ninety with spiral tooth gear and has some additional information from my manual. It was published in 1922.

I also was able to borrow a Model T Ford Front and Rear Axles comprehensive guide from 2003 by Glen Chaffin.

Thanks for all your help. We should be working on assembly in the next week.

I have located a bearing lock sleeve. Now to install the parts and see how everything fits. Looking forward to getting the rearend back under the Chevy and being able to move the car again. Thanks for all the help.